-

Download the e-Guide

-

Product Solutions

-

Webinar

-

Case Study

Working at height remains one of the most hazardous activities within the industrial and construction sectors. In addition to fall risks, the vertical workplace may contain other hazards: exposure to harmful chemicals including, cleaning products, paints, and solvents, and hazardous dusts, such as asbestos and polychlorinated biphenyls (PCBs). Mitigating multiple risks presents unique challenges for health & safety managers because it involves the specification of several diverse types of Personal Protective Equipment (PPE) – all of which need to work in harmony to achieve the necessary levels of worker protection.

Working at Heights e-Guide

This e-Guide provides a comprehensive overview of the complexities involved in selecting and managing PPE for working at heights. It outlines the multiple risks associated with aerial work, the critical role of PPE in mitigating these dangers, and the legal frameworks governing workplace safety. Using the challenges of deploying protective chemical coveralls with safety harnesses as an example, the e-Guide then considers the difficulties of ensuring PPE compatibility and explains how DuPont is addressing these issues through recent developments in protective garment design.

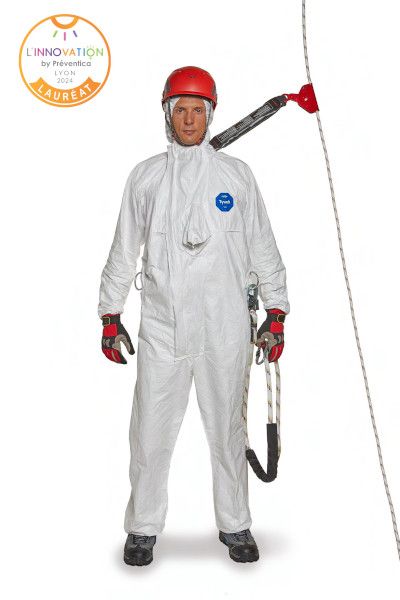

Elevating safety through new garment design

DuPont chose to work with safety harness manufacturers to develop a protective garment that could be worn over a full-body harness, protecting both the harness and the wearer from chemical hazards. The development process considered the specific requirements of full-body harness wearers and recognized the performance differentiators in designing a garment that is compatible with such harnesses.

Key design features are:

Explore the Product Portfolio

- <b>Tyvek® 500 HP TY178S HP </b>

Award-winning innovation

The new Tyvek® 500 HP TY178S HP garment offers a unique solution - protection of both the wearer and the full-body harness - by providing a barrier between the user and the particle or light liquid aerosol hazards in the environment.

- <b>Tyvek® 500 HP TY198S HP</b>

The Tyvek® 500 HP offers the wearer full protection by housing the rope lanyard within a sealed compartment giving access to the harness worn underneath, helping to maintain an effective barrier between the user and equipment and any chemical threat.

Multiple Benefits

Using this new harness-compatible coveralls brings far-reaching benefits.

Improved compliance

The garment provides an added layer of protection against chemical hazards without compromising the integrity or functionality of compatible harnesses, which helps improve compliance.

Enhanced efficiency

Easy access to the D-Rings on compatible harnesses means that setup and usage time may be significantly reduced, which helps workers to focus on their tasks without interruption, enhancing productivity.

Lower costs

Helping to extend the wear life of full-body harnesses reduces the frequency of replacements and maintenance, lowering long-term costs

Better quality

With the assurance of DuPont™ Tyvek® 500 HP garments, wearers can be encouraged to invest in superior, more durable harnesses that offer enhanced fall protection and improved return on investment.

Webinar

Ending the Dilemma: Can I Wear Safety Harness with a Chemical Protective Coverall?

Webinar Highlights:

Identify Risks: Gain insights into common hazards encountered while working at heights, particularly when using chemical protective coveralls alongside safety harnesses.

Understand Compatibility Challenges: Explore the complexities involved in selecting protective equipment that adheres to safety regulations without compromising on function.

Innovative Solutions – Live Demonstration: Watch a live donning and doffing exercise featuring the award-winning DuPont™ Tyvek® 500 HP coverall model 178, highlighting compatibility with the safety harnesses.

Featured Case Study

DuPont Designs Chemical Protection for Full-Body Harness Wearers, Leveraging MSA’s Expertise in Fall Protection

As a leading PPE manufacturer, DuPont was determined to develop a garment that would improve chemical protection for workers and their safety harnesses because it could be worn over the harness rather than beneath it. To achieve this aim, DuPont needed to work with a company with in-depth knowledge of fall protection. Safety expert MSA recognised the project’s potential immediately, resulting in close collaboration.