PROTECTIVE CLOTHING IN THE PHARMACEUTICAL INDUSTRY

Tyvek® helps to control contamination and protect against particles, ensuring safety of the pharmaceutical staff, as well as sensitive pharmaceutical products and processes

When worn in cleanrooms, manufacturing sites and research laboratories, protective clothing made of DuPont™ Tyvek® helps to control contamination and protect against particles, biological and chemical hazards, to ensure safety of the pharmaceutical staffs, as well as sensitive pharma products and processes.

The pharmaceutical industry is one of the most dynamically developing segments in the modern European economy. The rapid development in research, advancements in technology and science, drive the progress of this segment, constantly improving the quality and length of human life. Market trends show this sector as very competitive with pressure to increase efficiency, optimize and improve manufacturing processes and prove constant high quality of products. On the other hand, the directives and guidelines of manufacturing, handling and packaging which regulate this industry such as those created by the FDA, WHO or European Union, are getting more stringent every year, especially when it comes to sterile product manufacturing. To facilitate achieving goals and quality it is important to use the proven products and services which help companies develop and improve day to day activities. DuPont has a wide range of protective coveralls and accessories suitable for various pharmaceutical applications, from general activities like maintenance up to specialized activities performed in controlled environments.

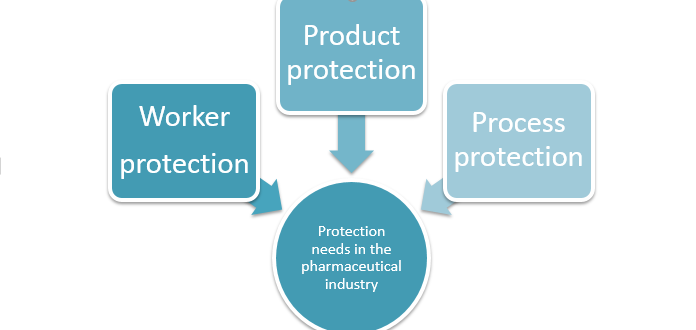

Triple protection need

Employees working in the pharmaceutical segment often encounter many on the job hazards as they come into contact with chemical substances, biological agents and drugs. Workers in the pharmaceutical industry require different types of protection varying from protection against non-hazardous and hazardous particles, liquid pressurized chemicals, liquid aerosols to mist and others. Chemicals they have to face may be among others: phenols, ammonium, cytostatic substances, antibiotics or toxic agents. It is important to guarantee the safety of pharmaceutical staff, however it is equally important to protect sensitive pharmaceutical products and processes, not only from hazardous contaminants like chemicals but also from particles and microorganisms which can harm their quality.

Contamination control in cleanrooms

In many cases pharmaceutical personnel has to work in special conditions, in closed areas called cleanrooms, to execute activities, observe processes, perform quality checks and other activities to ensure the best quality and cleanliness of their products.

A cleanroom can be defined as: “a room where the concentration of airborne particles is controlled, and which is constructed and used to minimize the introduction, generation and retention of particles inside the room and in which other relevant parameters such as temperature, humidity and pressure are controlled as necessary”[1]

Contamination control is the key element in cleanrooms. Contaminants can be understood as any disturbing effects of a solid, liquid, gaseous, thermal or electromagnetic nature capable of having a negative influence on the course of the process and quality of a product. Contamination by people is one of the most common types of contamination as people generate particles, eject saliva droplets, carry particles, distribute particles, make contact with various surfaces and can transfer particles and cause cross contamination. Did you know that by sitting quietly a human body sheds 100 000 skin particles in a minute? When walking at the speed of 8km/h a human body sheds 10 million particles/min!

These contaminants (particles and microorganisms) are often not visible with a naked eye, but can harm critical products and affect their quality. On the other hand, it is also important to protect the personnel working in cleanrooms. The most common hazards workers are exposed to in cleanrooms are dry particles, hazardous powders, non-hazardous /hazardous liquids and other hazards, therefore it is important that they are protected against these hazards to avoid contamination or health risks. For more information on cleanroom protection go here.

Protection against biological agents

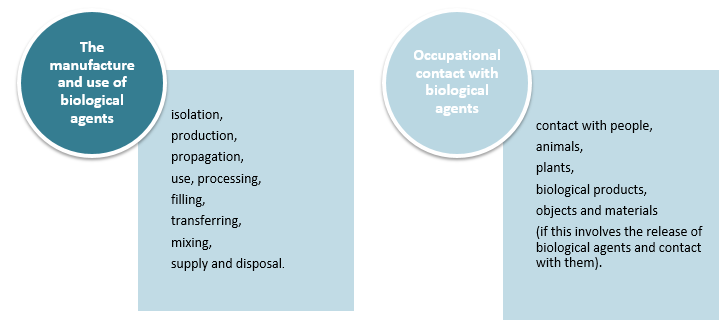

The term “Biological agents” refers primarily to micro-organisms such as bacteria, viruses and fungi. The EU directive 2000/54/EC referring to the protection of workers from risks related to exposure to biological agents at work, also refers to biological materials, including those which have been genetically modified, as well as biological agents. What is important is that these substances can be pathogenic, sensitizing or toxic. Biological agents have the ability to adversely affect human health in a variety of ways, ranging from relatively mild allergic reactions to serious medical conditions, including death. For pharmaceutical companies, it is necessary to provide protection against contamination by biological agents for workers and products.

Activities which can bring into contact with bacteria, viruses or fungi.

Key PPE considerations in the pharma industry

The key role of protective clothing in pharma is the protection of the personnel from hazardous chemical and biological substances such as infective agents and others substances which may harm their health. Equally important is the protection of the product and the process from human contamination and cross-contamination. Selection of the right protective clothing depends on the application type, contamination type and other criteria (for more on chemical risk assessment please go here) however there are some, key aspects which have to be taken into consideration when selecting the right PPE:

Key aspects of selecting the right PPE in the pharmaceutical industry.

· Quality

· Comfort

· Microbiological protection

· Regulatory Compliance with norms and standards

· Particle emission

· Donning-doffing procedures

· Cost

[1] NEN-EN-ISO 14644-1:1999 Clause 2.1.1

Controlled environments

& cleanroom protection

DuPont offers a full spectrum of cleanroom garments and accessories for greater safety, comfort, protection against contamination, and more.

Nomex® for laboratory protection

FR clothing made with DuPont™ Nomex® helps minimize potential burn injury during short-term exposure to flames and helps provide valuable escape time.